The St. Lawrence Seaway

A Vital Waterway

Opening of the 2019 Navigation Season: Federal Kumano transits the St. Lambert Lock on March 26th

The Seaway Story

The Great Lakes and St. Lawrence River have served as major North American trade arteries since long before the U.S. or Canada achieved nationhood.

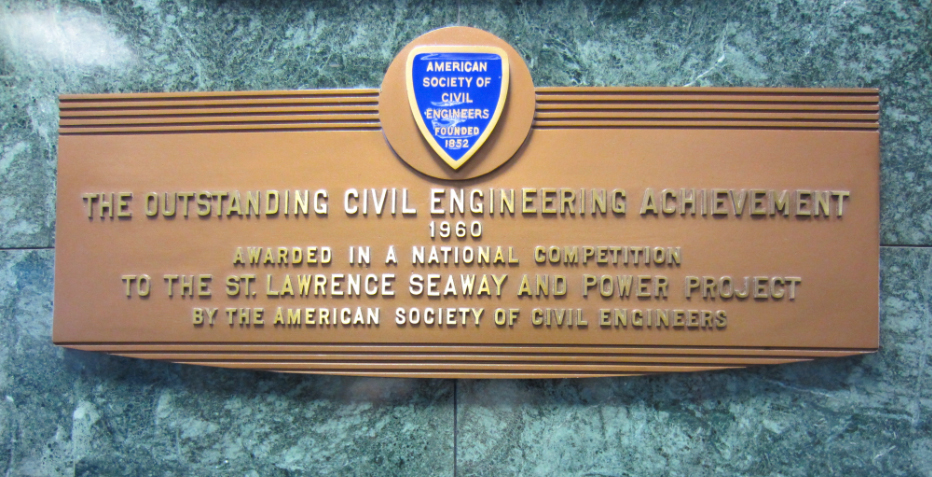

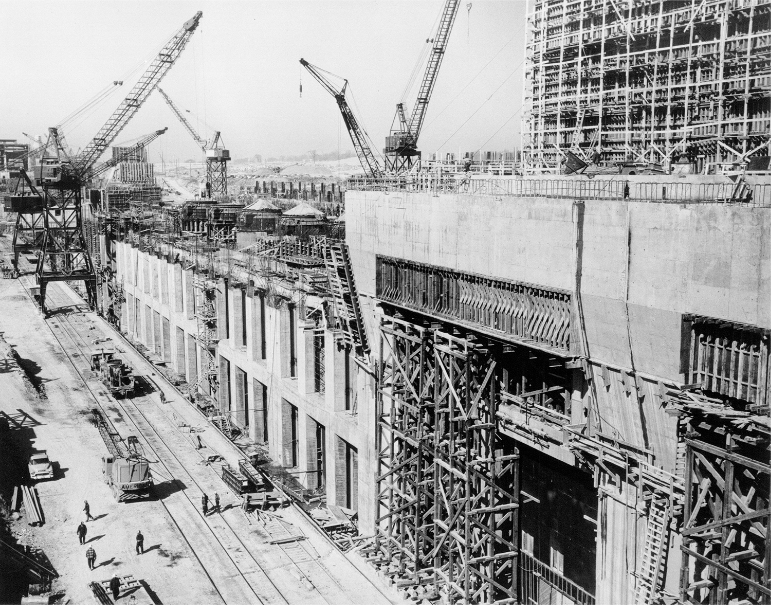

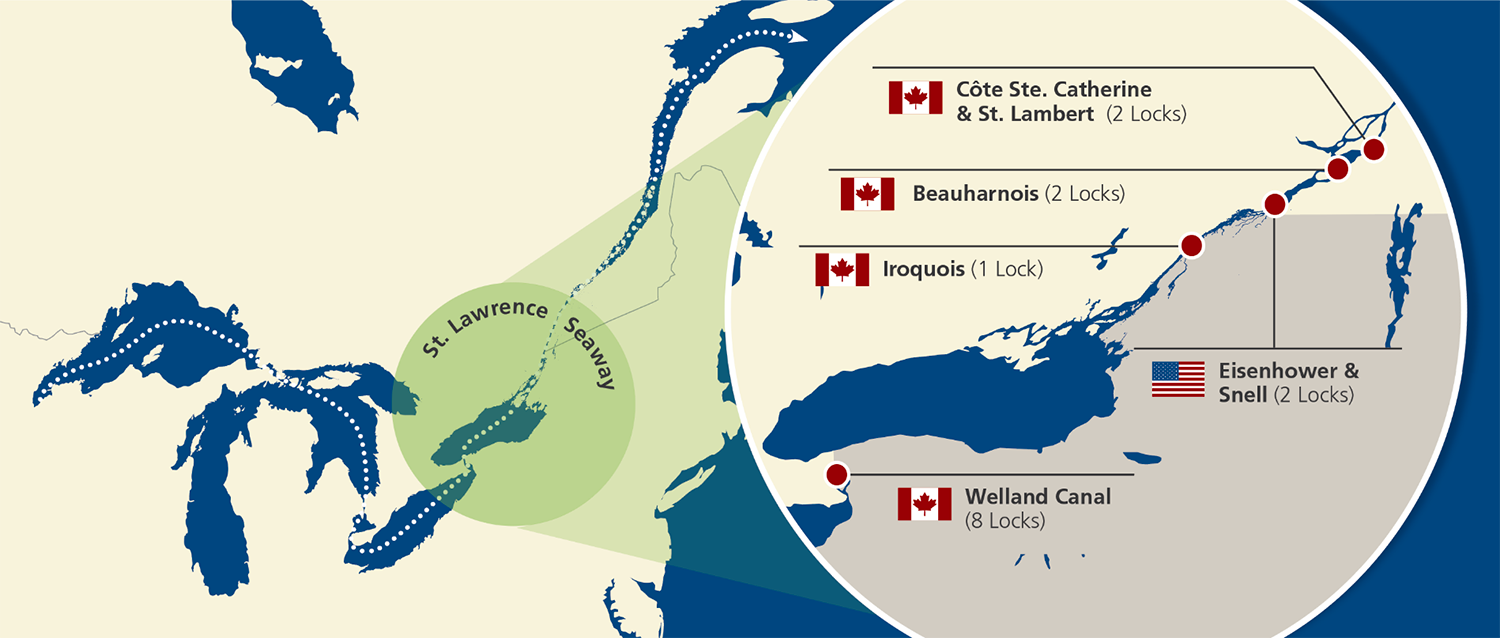

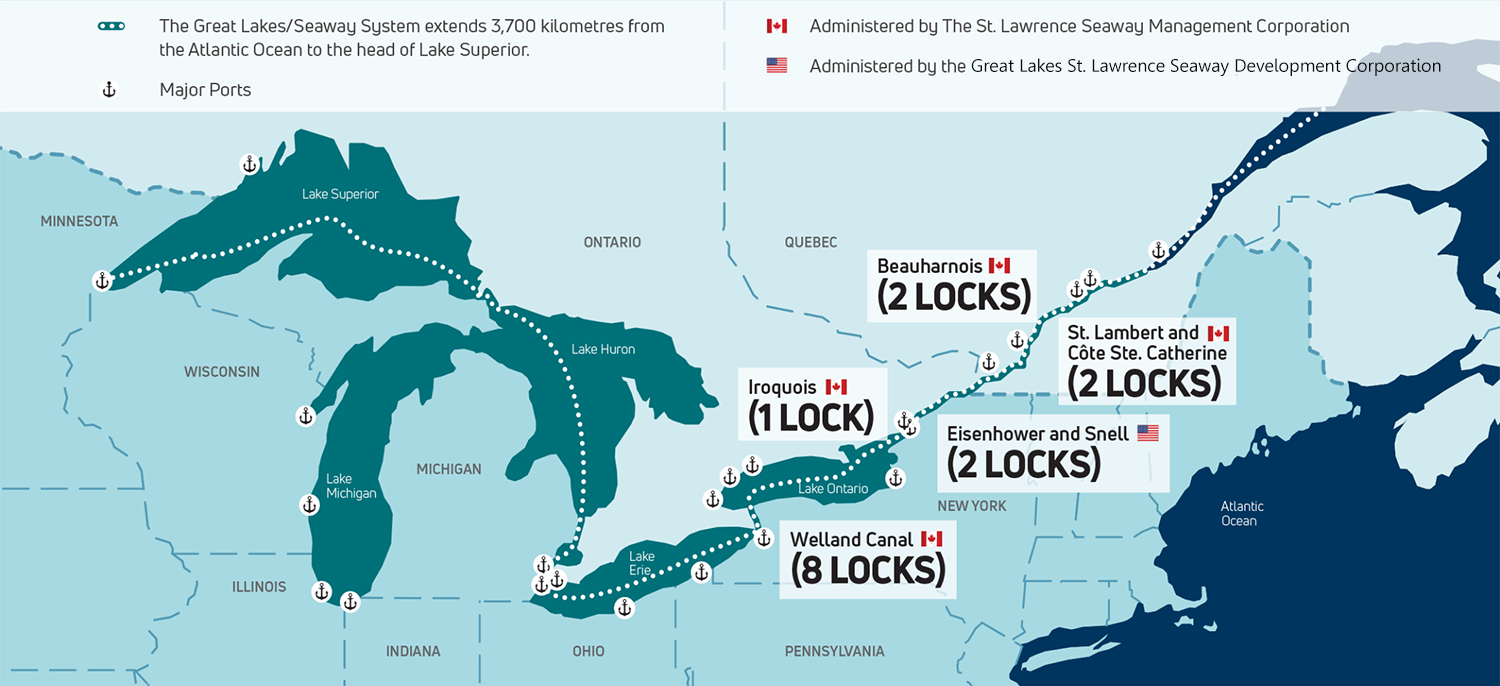

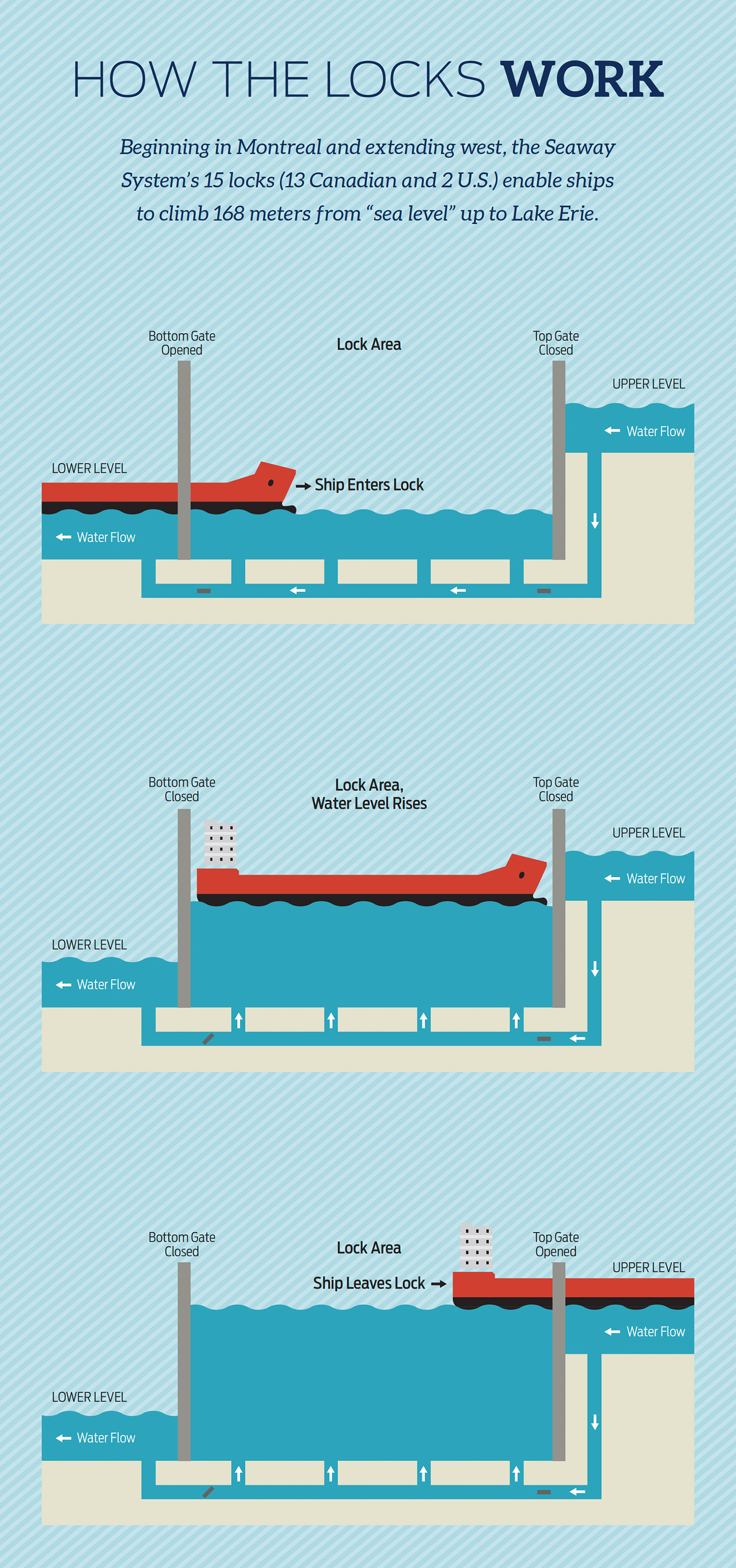

A new era in marine transportation was made possible by construction of the 306-kilometer (189-mile) stretch of the St. Lawrence Seaway between Montreal and Lake Ontario during the mid to late 1950s. Recognized as one of the most challenging engineering feats in history, seven locks were built, five Canadian and two U.S., in order to lift vessels 246 feet (75 meters) above sea level as they transit from Montreal to Lake Ontario.

Initiated in 1954 and completed in 1959, building the Seaway required:

- Some 22,000 workers

- Moving 210 million cubic yards of earth and rock

- Pouring over 6 million cubic yards of concrete

The Seaway is considered to be one of the engineering marvels of the 20th century

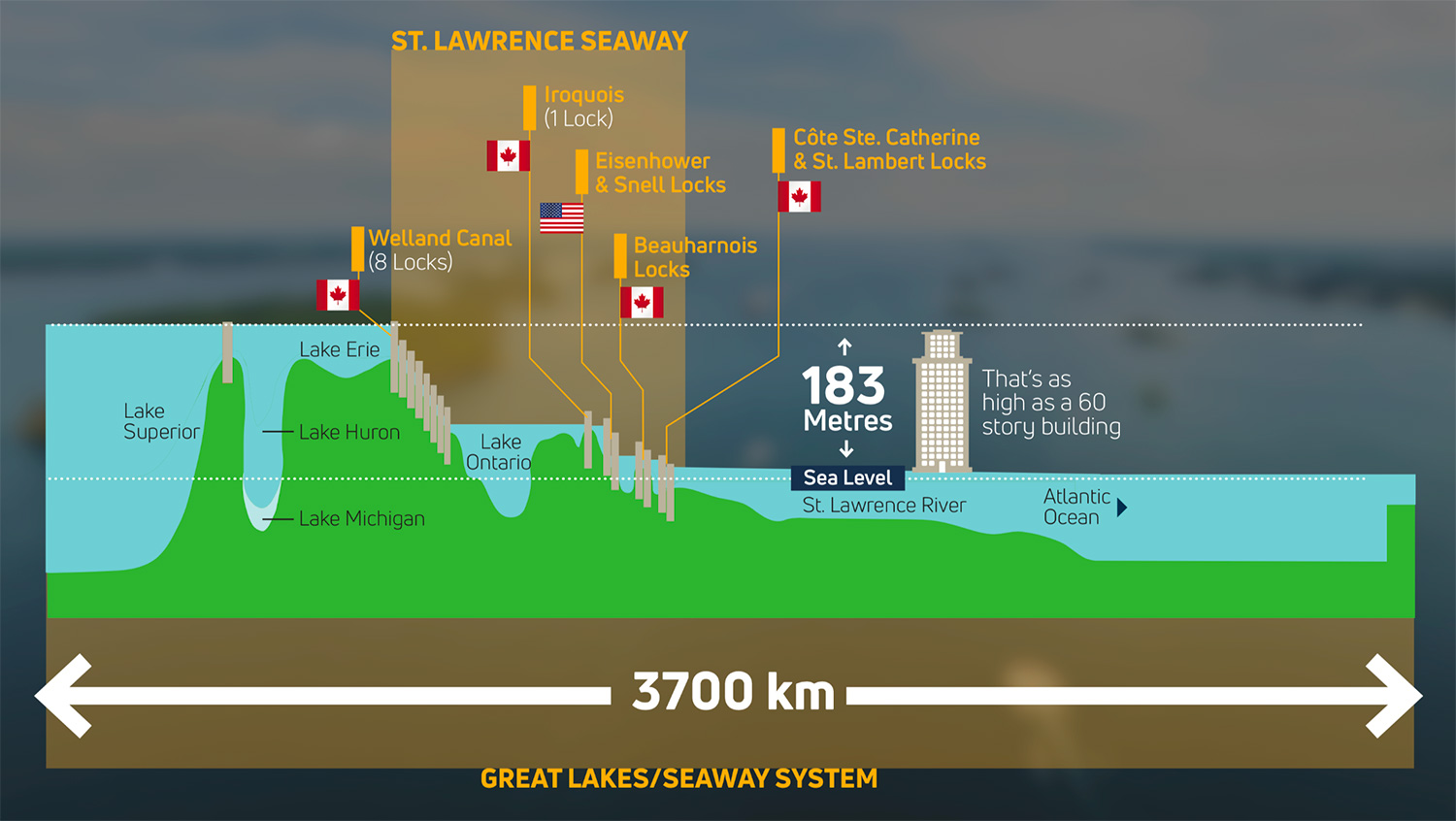

Combined with the eight locks of the Welland Canal, which link Lake Ontario to Lake Erie, the binational St. Lawrence Seaway’s 15 locks (13 Canadian and 2 American) allow ships to transit between Montreal and Lake Erie, a difference in elevation of 168 metres. The “Soo” Locks, managed by the U.S. Army Corps of Engineers, enable ships to reach Lake Superior, which is 183 metres above sea level.

History of the Seaway’s Two Sections:

Welland Canal Section (consisting of eight locks) was completed in 1932.

The Montreal – Lake Ontario Section (consisting of seven locks) was completed in 1959.

The combination of these two sections forms the St. Lawrence Seaway, which permits ships to transit between “sea level in Montreal to Lake Erie.

Note: The U.S. Army Corps of Engineers runs the Soo Locks, which permits ships to gain access to Lake Superior

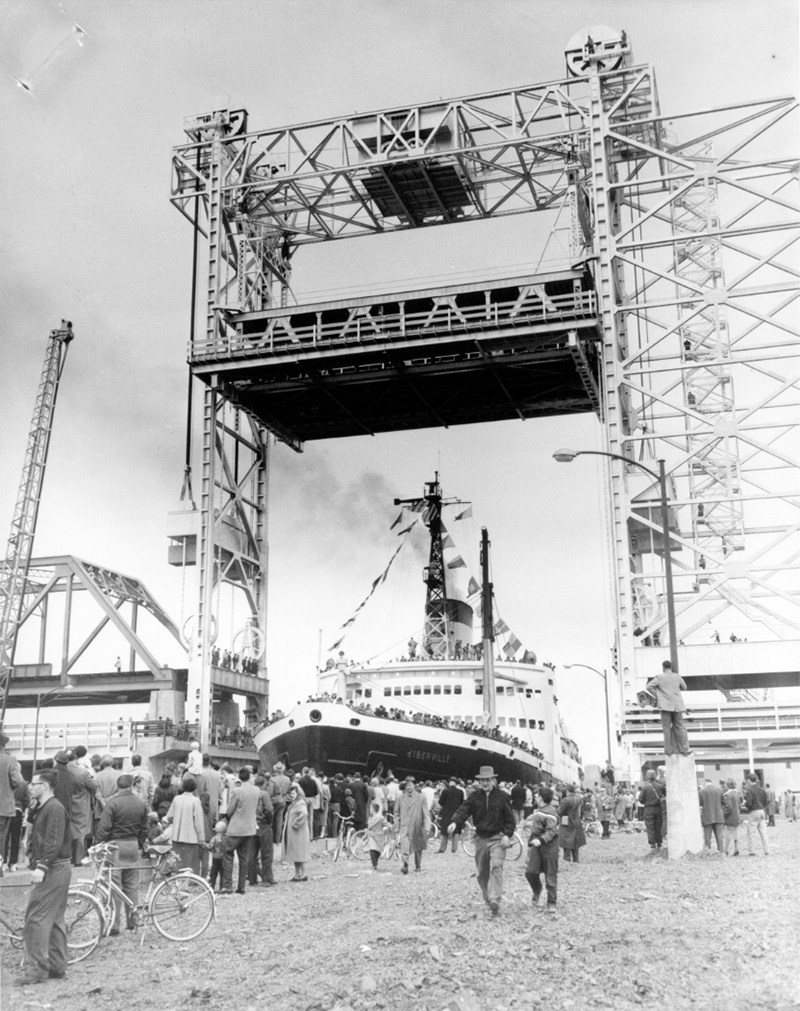

On April 25, 1959, the icebreaker “D’IBERVILLE” began the first through transit of the St. Lawrence Seaway which was officially opened by Her Majesty Queen Elizabeth II and the President Dwight D. Eisenhower of the United States on June 26th of that year.

Today, the waterway remains a fine example of the spirit of co-operation that can exist between two nations and its successful operation is a tribute to the ingenuity, capability and perseverance of all those who had a hand in its realization. In 2020, it is expected that the St. Lawrence Seaway will reach a total of three billion tonnes of cargo having transited its locks since it initially opened in 1959. This rapidly approaching milestone serves as a strong testimony to the Seaway’s ongoing role as a vital trading gateway connecting the heart of North America to over 50 trading nations across the globe.

Administration of the St. Lawrence Seaway

The St. Lawrence Seaway was built as a binational partnership between the U.S. and Canada through international agreements that carry the weight of treaties, and continues to operate as such. Administration of the waterway is shared by two entities, the Great Lakes St. Lawrence Seaway Development Corporation in the U.S., a federal agency within the U.S. Department of Transportation, and The St. Lawrence Seaway Management Corporation in Canada, a not-for-profit corporation established by the Government of Canada.

The waterway remains a fine example of the spirit of co-operation that can exist between two nations and its successful operation is a tribute to the ingenuity, capability and perseverance of all those who had a hand in its realization. The two Seaway Corporations have an excellent working relationship, and continue to work together on a daily basis in administering Seaway operations, supporting a vital trade gateway connecting the heart of North America to over 50 nations across the globe.

The Seaway: Ready for the Future

Today, the Great Lakes / Seaway System serves as a Key Supply Chain for the world’s 3rd largest economy.

According to a special report compiled by BMO Capital Markets, the eight states and two provinces that border the Great Lakes/St. Lawrence Seaway System generate an immense economic impact within North America.

- GDP of US $6 trillion (2017 est)

- Population: 108 million (2017)

- 30% of Canadian/U.S. economic activity

- 52 million jobs

- 30% of Canadian/U.S. workforce

- More than half of Canada/U.S. cross-border trade

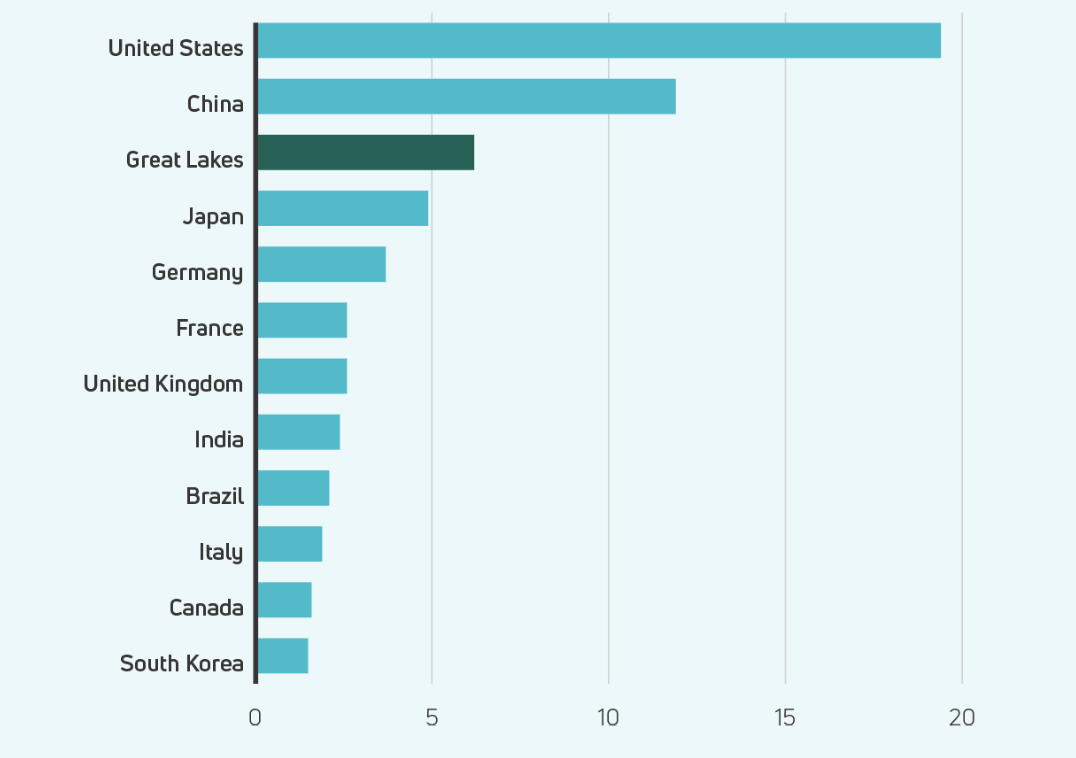

GROSS DOMESTIC PRODUCT

(US $ trillions)

The Great Lakes–St. Lawrence region boasts a massive geographic footprint, and is a major driver of the North American economy. With economic output estimated at US$6 trillion in 2017, the region accounts for 30% of combined Canadian and U.S. economic activity and employment. The region’s output ranks ahead of Japan, Germany, the U.K. and France, and it would rank as the third largest economy in the world if it were a country, behind only the U.S. and China—notably, the region overtook Japan a few years ago. Quite simply, the economic importance of the region can’t be overstated.

(Source: BMO Capital Markets, Spring 2018)

The Great Lakes/Seaway System is a 3,700 km “marine highway” that extends from the Atlantic Ocean to the Great Lakes. Over 200 million tonnes of cargo travel on the waterway on an annual basis.

For every ton of cargo, there are scores–often hundreds–of human faces behind the scenes. On board, there are the mariners themselves, while shore side there are lock operators and longshoremen, vessel agents and freight forwarders, ship chandlers and shipyard workers, stevedores and terminal operators, Coast Guard personnel and port officials, railroad workers and truck drivers–wide web of service providers.

CARGO MOVING ON THE GREAT LAKES/SEAWAY WATERWAY SUPPORTS:

USD 50.9 Billion

CAD 66.1 Billion

in Economic Activity

USD 23.3 Billion

CAN 30.2 Billion

in Wages

356,858

Jobs

Source: The Economic impacts of the Great Lakes / St. Lawrence Seaway Waterway (Martin Associates, 2023)

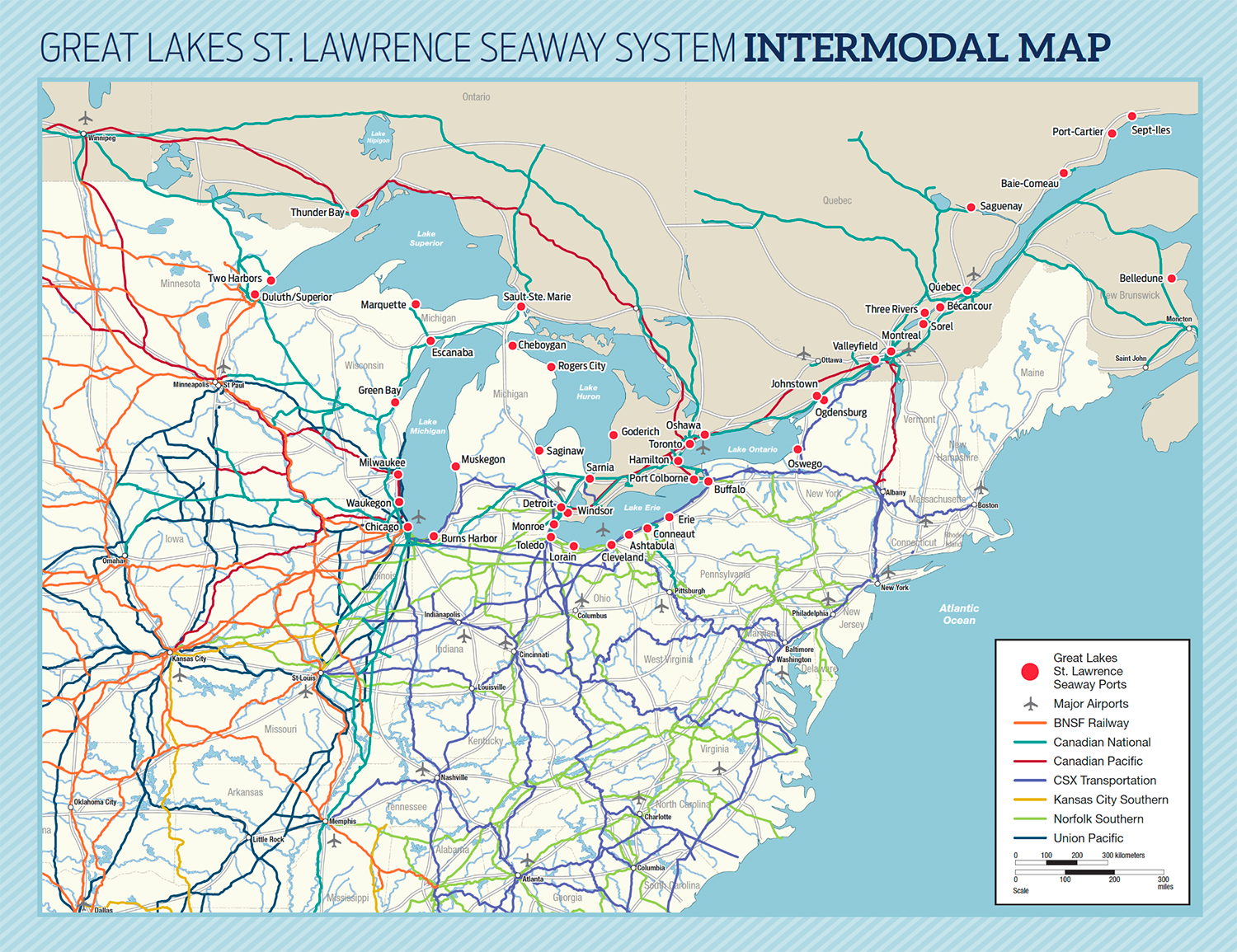

From Great Lakes / Seaway ports, a multi-modal transportation network fans out across the continent.

The St. Lawrence Seaway – A Vital Waterway

The binational St. Lawrence Seaway’s 15 locks (13 Canadian and 2 American) serve as the linchpin within the broader waterway, connecting the lower St. Lawrence River to the Great Lakes, enabling ships to transit between Montreal and Lake Erie, a difference in elevation of 168 metres. The “Soo” Locks, managed by the U.S. Army Corps of Engineers, enable ships to reach Lake Superior, which is 183 metres above sea level.

Great Lakes / St. Lawrence Seaway (Highway H2O) Facts

Distance from the Atlantic Ocean to Duluth, Minnesota on Lake Superior = 2,038 nautical miles (2,342 statute miles or 3,700 kilometres), 8.5 sailing days. The waterway includes some 245,750 square kilometres (95,000 square miles) of navigable waters.

In a typical year, about 25% of Seaway traffic travels to and from overseas ports, especially in Europe, the Middle East, and Africa.

The waterway includes some of North America’s largest ports, part of an excellent intermodal transportation network, and has maintained a near-perfect record of trouble-free navigation through ongoing improvements and meticulous maintenance for more than 50 years.

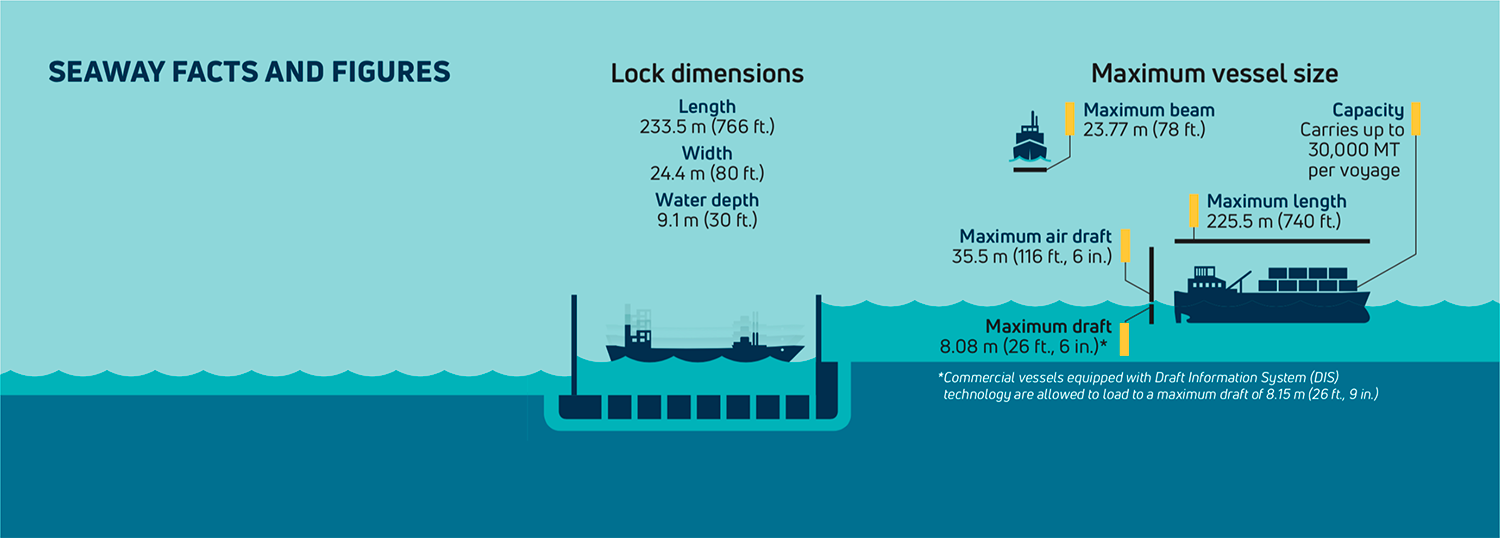

Seaway Locks

Each lock is 233.5 metres long (766 feet), 24.4 metres wide (80 feet) and 9.1 metres deep (30 feet) over the sill. A lock fills with approximately 91 million litres of water (24 million gallons) in just 7 to 10 minutes. Getting through a lock takes about 45 minutes.

Credit: Harbor House Publishers

Seaway Ships

Ships measuring up to 225.5 metres in length (or 740 feet) and 23.8 metres (or 78 feet) wide (also known as the ship’s “beam”) are routinely raised to more than 180 metres above sea level, as high as a 60-story building. These ships can be twice as long and half as wide as a football field and carry cargoes the equivalent of 30,000 metric tonnes.

The primary types of ships on the Seaway fall into three main groups:

“LAKERS“

“Lakers” are built specifically for use within the Great Lakes / Seaway System, and rarely exit the waterway. They are characterized by a design that includes vertical sides and a snub-nosed bow, to maximize cargo carrying capacity within the confines of the Seaway‘s lock dimensions. Some lakers also are equipped with a self-unloading boom that contains a conveyor belt, allowing the ship to position its boom and unload bulk cargo (such as stone or road salt) directly onto a shore-side dock or wharf.

“SALTIES“

“Salties” are ocean going ships that enable trade with nations overseas. They are characterized by a V-shaped hull, sharp bows, and in many cases, cranes mounted on the deck to facilitate the loading and unloading of cargo.

“TUG-PROPELLED BARGES“

Tug-propelled barges consist of a tug fitted into a specially designed barge. The nose of the tug is secured within the stern of the barge, creating a very stable unit that can be used to move a variety of cargoes, depending upon the type of barge that the tug is paired up with.

Ships Move a Wide Variety of Cargo

All sectors of the economy benefit

The St. Lawrence Seaway serves miners, farmers, factory workers and vast array of other commercial interests from the western prairies to the eastern seaboard.

Photo: Thunder Bay Port Authority

GRAIN

Wheat, corn, soybeans, barley, canola, and oats are among the top commodities shipped.

Photo: McKeil Marine Ltd.

DRY BULK

Dry bulk cargoes are unpackaged commodities, such as stone/gravel, sand, salt, cement, potash, and gypsum.

Photo: Ron Samson

IRON ORE

Iron ore is the principal ingredient in steel, an essential building block in hundreds of manufacturing industries.

Photo: Thunder Bay Port Authority

GENERAL CARGO

General cargo includes a wide range of products such as iron and steel slabs, machinery, and wind energy turbines.

Photo: Hamilton Port Authority

LIQUID BULK

Liquid bulk products shipped include refined petroleum products (gasoline, diesel, kerosene, jet fuel) and alternate fuels (ethanol, biodiesel).

The Seaway Moves Cargo Efficiently and Safely

Moving cargo efficiently and safely is vital to the Seaway’s competitive position as a trade gateway.

The Great Lakes St. Lawrence Seaway Development Corporation (US) and the St. Lawrence Seaway Management Corporation (Canada) continue to work with industry partners to reinforce the Seaway’s efficiency and safety. From being the first inland waterway to implement the Automatic Identification System in 2003, which enables the precise monitoring of ship locations by satellite, to the implementation of the Draft Information System which provides a 3-D model of the channel and enables ships to safely carry up to 400 additional tonnes of cargo per voyage, the Seaway Corporations have been at the forefront of progress within the marine industry.

The recent implementation of Hands Free Mooring (HFM) represents the greatest advancement in Seaway operations since its inception in 1959.

HFM unit being installed at the Eisenhower Lock (Massena, NY)

Each lock is equipped with three HFM units, which reach out to secure a ship during a lockage, utilizing vacuum pads instead of traditional wire or rope lines. Ships are held by the mooring units which move up or down on rails recessed within the lock wall as the ship is raised or lowered. Once the ship is at the desired level, the mooring units release their grip, allowing the ship to proceed on its journey.

Each high-lift Seaway lock is equipped with three HFM units (Lock 8 in the Welland Canal and the Iroquois Lock, which serve as a low-lift locks, are not equipped with HFM and utilize a “walk-thru” procedure by which ships can advance through the lock without tying up)

Ship secured by HFM at Lock 3 Welland Canal (no need for wire or rope lines)

With the elimination of tie-up lines for most vessels, Seaway employees and vessel crews enjoy less manual labour, safety is improved, and ships experience less “wear and tear” as they enter and exit locks.

The Canadian locks have also been converted to remote control operation, and are managed from two Operations Control Centres, located in St. Lambert (Québec) and St. Catharines (Ontario).

Seaway Operations Control Centre (St. Lambert, Québec)

The Seaway Corporations have also worked closely together to optimize the Seaway’s navigation window by incrementally adding days to the season, which today typically extends from the third week of March to late December. As a result, carriers have an additional week of navigation (on average) each season when compared to the late 1990s.

Seaway Operations Control Centre (St. Catharines, Ontario)

The St. Lawrence Seaway: Ready for the Future

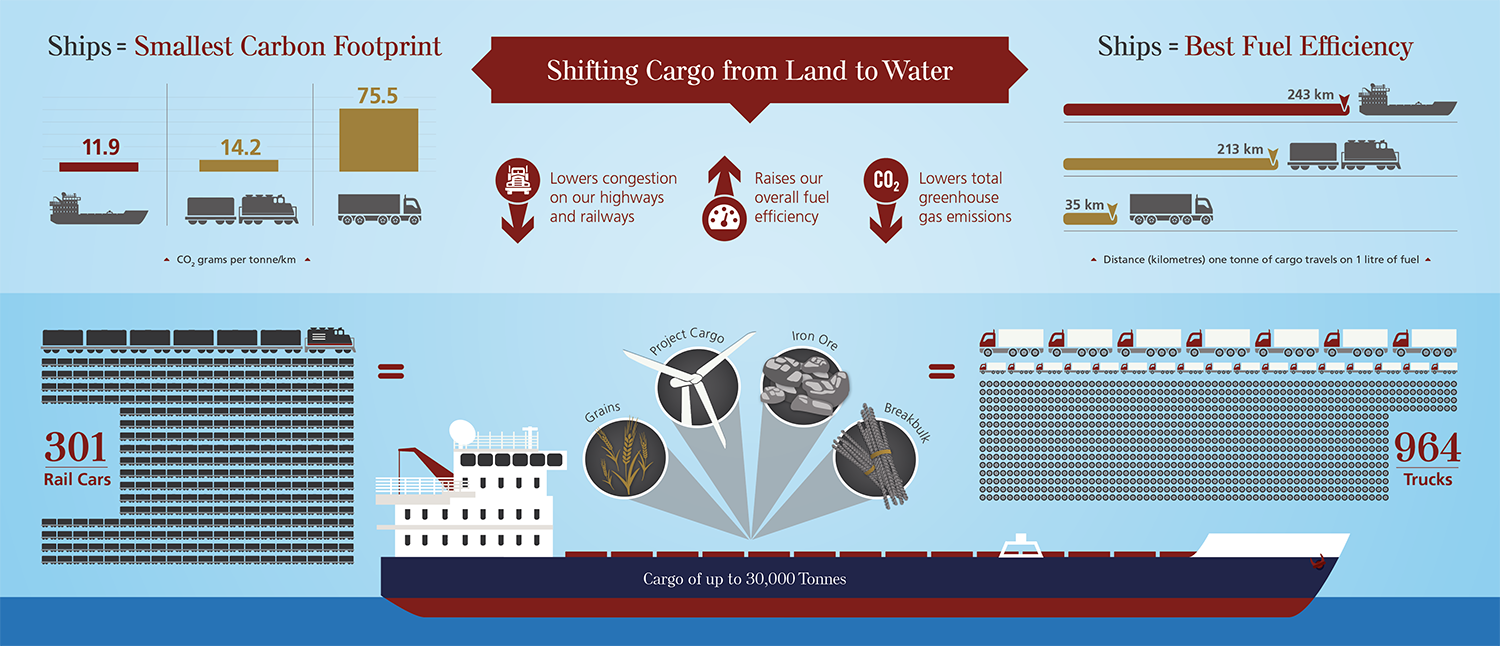

As the most energy efficient transportation mode, with the lowest carbon footprint, moving more cargo using the Great Lakes/Seaway System is an excellent way of supporting sustainable growth while easing congestion on land.

With strong advancements in safety, reliability, and efficiency, the stage has been set for a St. Lawrence Seaway that will effectively serve its stakeholders for decades to come.

Photo: Courtesy of John Gleed—Copyright stlawrencepiks.com